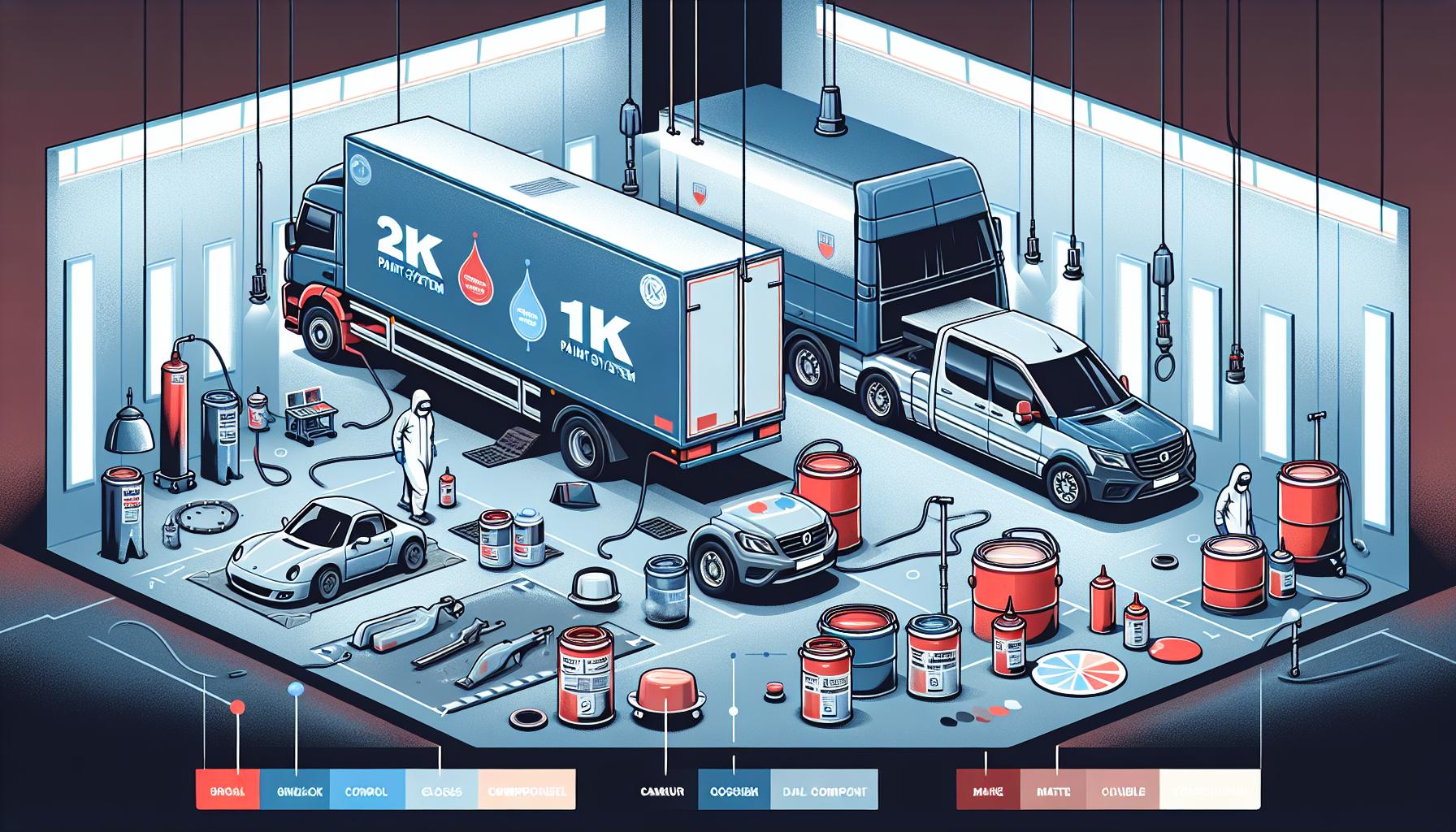

2K vs 1K Paint Systems: What Commercial Body Shops Need to Know

1. Demystifying 2K and 1K Paint Systems

Table of Contents

- 1. Demystifying 2K and 1K Paint Systems

- 2. Benefits of 2K Paint Systems for Commercial Applications

- 3. Advantages of 1K Paint Systems for Quick Jobs

- 4. Common Mistakes in Choosing Paint Systems

- 5. Emerging Trends in Automotive Paint Technologies

- 6. Cost Comparison of 2K vs 1K Systems

- 7. How to Implement 2K Paint Systems in Your Shop

- 8. The Environmental Impact of Paint Systems

Introduction

Navigating the world of automotive paint systems can be complex for commercial body shops. With the right knowledge, repairers can make informed decisions that lead to quality finishes, customer satisfaction, and business growth. This blog post explores the critical differences between 2K and 1K paint systems, providing commercial, private, and personal vehicle repairers with valuable insights. With a confident, conversational, and data-driven approach, this guide serves as an essential resource in choosing the best paint products for body shops.

1. Demystifying 2K and 1K Paint Systems

Benefits of 2K Paint Systems for Commercial Applications

2K paint systems, a staple in commercial body shops, offer numerous advantages, particularly regarding durability and efficiency. These two-component systems, which include a base and a hardener, cure through a chemical reaction, providing a robust finish that outperforms traditional 1K (single-pack) options.

- Durability and Protection: 2K paint systems provide long-lasting resistance to scratches, chemicals, weather conditions, UV exposure, and corrosion, crucial for vehicles frequently subjected to harsh environments.

- Efficiency and Time Savings: These systems enable faster drying times, reducing overall cycle times and allowing quicker project turnarounds.

- Superior Finish Quality: They deliver consistent, high-quality finishes with a high gloss and exceptional colour consistency.

- Ease of Application: Aerosol 2K products eliminate the need for mixing, guns, or compressors, minimising waste and enabling quick application.

In summary, the robust features of 2K paint systems make them the standard choice for commercial body shops seeking high-quality, long-lasting repairs.

2. Benefits of 2K Paint Systems for Commercial Applications

1K paint systems are increasingly popular in the UK automotive repair industry for quick jobs requiring efficient application and cost-effectiveness. They are a pragmatic choice for many repairers due to their user-friendly characteristics.

- Ease of Application: 1K paints are ready to use right out of the can, allowing for application with a spray gun, roller, or brush.

- Fast Drying Times: These paints typically dry to the touch within approximately four hours, allowing a second coat within 24 hours.

- Cost Efficiency: Generally more affordable, 1K paints reduce the initial investment for repairers.

- Cleaner Processes: They lack the intensive cleanup required for 2K systems and have lower toxicity, reducing the need for extensive PPE.

While 1K systems may not match 2K systems’ durability for high-wear areas, they provide an accessible, efficient, and economical solution for various automotive repair tasks.

3. Advantages of 1K Paint Systems for Quick Jobs

Common Mistakes in Choosing Paint Systems

In the selection between 1K and 2K paint systems, body shops often encounter several common mistakes that can affect the quality of their work. Understanding and avoiding these pitfalls can significantly enhance the durability and finish of the paint jobs.

- Incorrect Mixing Ratios: Failing to adhere to the specified hardener and activator ratios for 2K systems can lead to defects such as cracking and poor adhesion.

- Inadequate Application Environment: Excessive heat or humidity and insufficient flash time can lead to surface imperfections.

- Improper Substrate Preparation: Misapplying paint over incompatible surfaces can cause bubbles, peeling, and poor adhesion.

- Film Thickness Issues: Applying too little or too much paint can lead to uneven finishes and sagging.

- Neglecting Health and Safety: Proper respiratory protection and ventilation are essential when working with 2K systems containing isocyanates.

By addressing these common mistakes, body shops can improve their paint application outcomes and enhance customer satisfaction.

4. Common Mistakes in Choosing Paint Systems

Here is a concise table outlining common mistakes when choosing paint systems for commercial vehicles and their consequences.

Emerging Trends in Automotive Paint Technologies

The landscape of automotive paint technologies is rapidly evolving, influenced by demands for sustainability, advances in electric vehicle (EV) manufacturing, and stringent regulatory frameworks. These trends significantly affect how body shops in the UK approach paint selection and application.

Electric Vehicle-Specific Coatings

With the surge in EV production, there is a need for coatings specific to these vehicles, designed for various applications such as thermal management, sensor compatibility, and material versatility.

Water-Borne Paint Advantages

- Environmental Compliance: These paints reduce VOCs by up to 80% compared to traditional paints.

- Durability: Improved performance in gloss retention and durability makes them a viable alternative to solvent-based options.

Sustainability Initiatives

The UK automotive sector is increasingly focused on sustainability, exploring low-carbon and VOC-free technologies to meet both regulatory demands and consumer preferences.

Market Growth and Implications

The UK automotive OEM coatings market is projected to grow at a compound annual rate of over 3.4%, driven by initiatives phasing out gasoline and diesel vehicles by 2030.

5. Emerging Trends in Automotive Paint Technologies

Cost Comparison of 2K vs 1K Systems

When evaluating paint systems for body shops, understanding the cost implications between 2K and 1K systems is paramount. 1K paint systems are typically less expensive upfront, whereas 2K systems, despite their higher initial cost, often yield greater long-term savings due to their durability.

- Equipment and Setup: 1K systems require basic tools, while 2K systems need advanced tools for mixing and application, increasing initial setup costs.

- Labour and Efficiency: 2K systems may take longer to mix but cover better with fewer coats, reducing overall project time.

- Long-Term Savings: Vehicles painted with 2K finishes typically maintain their value better, making them a worthwhile investment.

Commercial body shops in the UK must weigh both initial costs and long-term benefits when selecting between 2K and 1K paint systems.

6. Cost Comparison of 2K vs 1K Systems

Understanding 1K and 2K Paint Systems for Commercial Vehicle Repairs

Body shops often face a decision when repainting commercial vehicles: to use 1K or 2K paint systems. For heavy-duty applications, 2K paints generally offer significant advantages in durability and adaptability to harsh conditions.

- Durability: 2K paints resist chemicals, UV rays, and abrasion, ideal for high-traffic vehicles.

- Application: 1K systems are straightforward, whereas 2K requires careful mixing and prompt application.

- Regulatory Considerations: Compliance regarding isocyanates used in 2K systems is essential.

While 1K paints are suitable for quick jobs, they are generally inadequate for vehicles exposed to severe conditions. 2K products, tailored for commercial applications, provide a long-lasting finish at a cost-effective price over the long term.

7. How to Implement 2K Paint Systems in Your Shop

The environmental impact of paint systems is crucial for body shops, especially when choosing between 1K and 2K systems. Understanding these differences is essential for regulatory compliance and promoting sustainability.

- Lower VOC Emissions: Water-based 1K coatings produce minimal VOCs, significantly reducing environmental pollution.

- Absence of Hazardous Materials: 1K systems do not require isocyanate hardeners, minimising hazardous waste disposal issues.

- Reduced Waste and Cleaner Processes: Easier cleaning and less hazardous waste compared to 2K systems.

In contrast, 2K systems often have higher environmental costs due to high VOC emissions, significant waste generation, and health hazards. For UK body shops, adopting 1K systems enhances sustainability and reduces compliance burdens, despite certain applications benefiting from the superior durability of 2K systems.

8. The Environmental Impact of Paint Systems

Understanding the Benefits of 2K Paint Systems

In the competitive arena of bodywork, choosing between 1K and 2K paint systems can significantly affect repair quality and longevity. For UK body shops, 2K paint systems offer outstanding durability and resilience against challenges presented by the local climate.

2K systems, requiring mixing with a hardener, provide enhanced toughness and resistance to UV rays, chemicals, and abrasions. These qualities are essential for vehicles exposed to harsh UK weather and road conditions. The initial drying time may be longer, but the resulting longevity often offsets additional effort.

- Professional Finish: 2K paints provide a high gloss that enhances vehicles’ appeal.

- Longevity: Fewer cosmetic damages result in prolonged intervals between repairs.

- Versatility: Suitable for a wide range of applications, ensuring robust protection from elements.

For commercial vehicle repairers, adopting 2K paint systems can lead to better results and reflect positively on repair shops’ reputations.

Sources

- Auto Paint – The Benefits of 2K Paints for Bodyshops

- PPG – Nexa Autocolor 2K Products

- BC Paints – What is 2K Paint and When Should You Use It?

- Hiwe – Understanding 1K vs 2K Paint Systems

- TA Industrial Paints – What Is the Difference Between 1K and 2K Paint?

- Online Paint Shop – What Is the Difference Between 1K and 2K Paints?

- Perpetual Paint – Automotive Paint: 1K vs 2K Mix Ratios

- On All Cylinders – 7 Common Paint Mistakes