The Science Behind UK Fire Protection Coatings: How They Safeguard Your Property

Key Takeaways

- Fire protection coatings are vital in safeguarding buildings against fire damage by delaying structural collapse.

- Intumescent coatings expand under heat, forming a protective char layer that insulates materials from fire.

- Cementitious coatings are robust and ideal for industrial applications, providing substantial fire resistance.

- Fire-retardant sprays are versatile, easily applied, and enhance fire safety for various materials.

- Compliance with UK regulations ensures that fire protection coatings meet safety and performance standards.

Fire Protection Coatings: Essential Defence Against Fires

Fire protection coatings serve as a crucial line of defence against the devastating effects of fires. These coatings are designed to protect buildings by delaying the structural damage that fires can cause. By doing so, they not only protect property but also save lives. Understanding how these coatings work and their applications is essential for anyone looking to enhance fire safety.

Introduction to Fire Protection Coatings

Fire protection coatings are specialized materials applied to surfaces to improve their resistance to fire. These coatings can be applied to a variety of substrates, including steel, wood, and fabric. They are an integral part of passive fire protection systems, which aim to contain fires and prevent them from spreading. The science behind these coatings involves complex chemical reactions that occur when exposed to heat.

Why Fire Protection is Crucial in the UK

In the UK, the importance of fire protection cannot be overstated. The region’s dense urban areas and historical buildings make fire safety a top priority. Fires can cause significant economic losses and endanger lives. Therefore, it is essential to implement effective fire protection measures. Fire protection coatings offer a practical solution, providing both immediate and long-term safety benefits.

- Fire protection coatings help meet stringent UK safety regulations.

- They are vital for preserving the integrity of historical and heritage sites.

- These coatings reduce the risk of fire-related injuries and fatalities.

Types of Fire Protection Coatings

There are several types of fire protection coatings, each with unique properties and applications. Understanding the differences between these coatings can help you choose the right solution for your needs. The three main types are intumescent coatings, cementitious fireproofing, and fire-retardant sprays.

Each type of coating has its own advantages and is suited for specific situations. Let’s explore these coatings in more detail to see how they function and where they are best applied.

“Intumescent coatings expand when exposed to high temperatures, forming a protective barrier that insulates materials from fire.”

Intumescent Coatings

Intumescent coatings are one of the most popular types of fire protection coatings. They are known for their ability to expand significantly when exposed to heat, creating an insulating char layer that protects the underlying material. This reaction helps to delay the spread of fire and provides additional time for evacuation and emergency response. For more information on fire-resistant solutions, explore fire-resistant paints that are essential for safety.

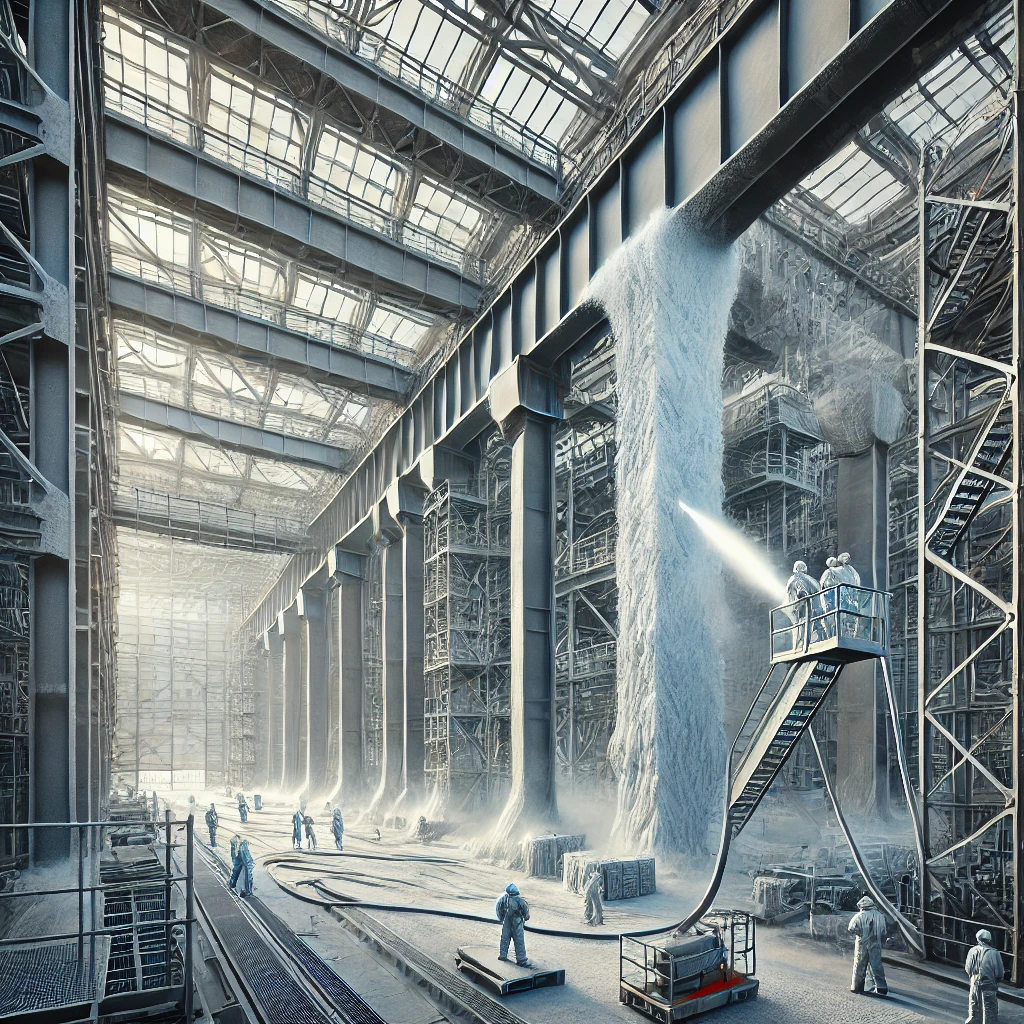

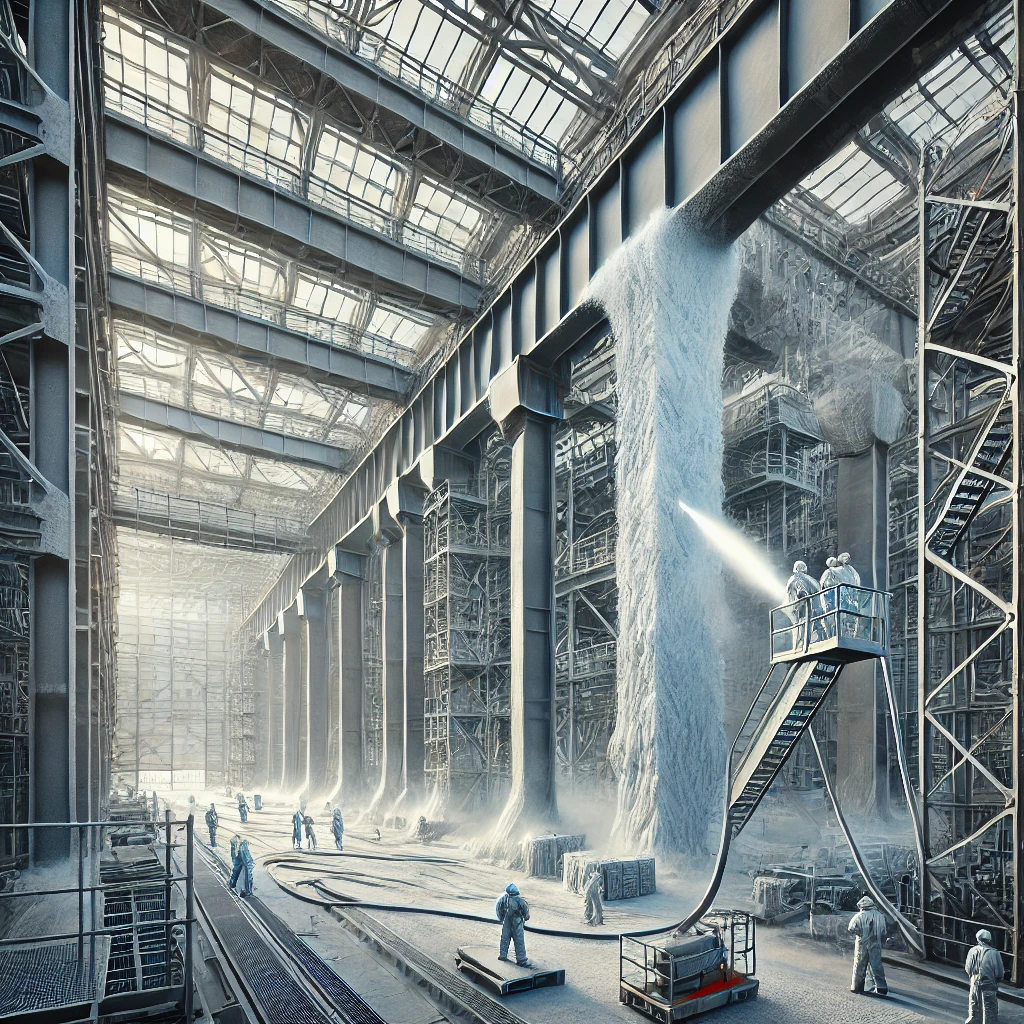

Cementitious Fireproofing

Cementitious fireproofing is another effective method for protecting structures from fire. These coatings are made from a mixture of cement and other materials, creating a thick, durable layer that can withstand high temperatures. Cementitious coatings are particularly well-suited for industrial applications where robust fire resistance is required. For more on the importance of protective coatings in industrial settings, check out this article.

In addition to their fire-resistant properties, cementitious coatings are also known for their ability to resist moisture and other environmental factors, making them a versatile choice for many applications.

- Cementitious coatings are ideal for use in harsh industrial environments.

- They provide excellent fire resistance for steel structures.

- These coatings are often used in conjunction with other fire protection systems.

Fire-Retardant Sprays

Fire-retardant sprays offer a flexible and easy-to-apply solution for enhancing fire safety. These sprays can be applied to a wide range of materials, including fabrics, wood, and even electrical components. They work by reducing the flammability of materials, helping to prevent fires from starting or spreading.

“Fire-retardant sprays are versatile and can be used on a variety of materials to enhance fire safety.”

Because of their versatility and ease of application, fire-retardant sprays are a popular choice for both residential and commercial settings. They provide an additional layer of protection that complements other fire safety measures.

Coating Type Description Key Benefits Typical Applications Intumescent Coatings Expand when exposed to heat, forming an insulating char layer – Aesthetically pleasing finish

– Can provide up to 120 minutes of fire protection

– Suitable for complex geometries– Commercial buildings

– Exposed steel structures

– Offshore platformsCementitious Coatings Made from cement and fibers, applied in thick layers – Excellent fire resistance

– Durable and robust

– Cost-effective– Enclosed areas in buildings

– Structural steel and concrete

– Petrochemical facilitiesEpoxy-based Coatings Two-part system forming a thick, durable film – Excellent hydrocarbon fire protection

– Highly corrosion-resistant

– Suitable for harsh environments– Offshore marine industries

– Chemical plants

– High-risk industrial settingsWater-based Intumescents Low-VOC, low-odor intumescent coatings – Best-in-class finish

– Environmentally friendly

– Easy to apply– On-site applications

– Interior steel structures

– Commercial buildingsSolvent-based Intumescents Intumescent coatings with solvent base – Fast-drying

– Weather-resistant

– Suitable for semi-exposed environments– Exterior steel structures

– Industrial facilities

– Bridges and infrastructureHybrid Intumescents Innovative coating combining benefits of different types – Fast cure times

– Single layer application

– Suitable for C1-C5 environments– On-site and off-site applications

– Complex steel structures

– High-performance requirementsRole of Heat Insulation and Conduction Reduction

Fire protection coatings play a critical role in insulating structures against heat. When a fire occurs, the intense heat can weaken materials, leading to structural failure. These coatings work by reducing heat conduction and providing a thermal barrier. This barrier slows down the transfer of heat to the material beneath, giving firefighters more time to control the blaze and preventing the rapid collapse of buildings.

“Intumescent coatings, for example, expand up to 50 times their original thickness, creating a protective char layer that insulates the structure from heat.”

This process is vital in maintaining the integrity of steel beams and other load-bearing elements. By delaying the temperature rise, fire protection coatings help preserve the structural stability of a building, reducing the risk of collapse.

Moreover, the insulation properties of these coatings can significantly reduce damage to the interior and contents of a building, further minimizing the financial impact of a fire. Learn more about fire-resistant paints and how they can protect your property.

Application and Activation Processes

- Surface preparation: Clean and prepare the surface for optimal adhesion.

- Coating application: Apply the fire protection coating using brushes, rollers, or sprays.

- Drying and curing: Allow the coating to dry and cure according to manufacturer instructions.

- Inspection: Conduct a thorough inspection to ensure proper coverage and thickness.

The application process for fire protection coatings is straightforward but requires attention to detail. Proper surface preparation is essential for ensuring that the coating adheres well and performs as expected. This often involves cleaning the surface and removing any contaminants that could interfere with adhesion.

Once the surface is prepared, the coating is applied using brushes, rollers, or sprays, depending on the type of coating and the surface area to be covered. It’s crucial to follow the manufacturer’s instructions for drying and curing times to achieve optimal performance.

After application, a thorough inspection should be conducted to verify that the coating has been applied correctly and meets the required thickness. This step ensures that the coating will provide the expected level of fire protection.

Applications and Benefits of Fire Protection Coatings

Fire protection coatings are versatile and can be used in various settings to enhance safety. Their applications range from commercial and industrial buildings to residential structures and historical sites. Each setting has unique requirements, and the benefits of using these coatings can be significant.

Commercial and Industrial Buildings

- Protects valuable assets and equipment from fire damage.

- Ensures compliance with fire safety regulations.

- Reduces insurance premiums by enhancing fire safety measures.

In commercial and industrial buildings, fire protection coatings are indispensable. They help protect valuable assets, machinery, and equipment from fire damage, minimizing downtime and financial losses. By enhancing the fire resistance of structural elements, these coatings also ensure compliance with safety regulations, which is crucial for business operations.

Additionally, investing in fire protection coatings can lead to reduced insurance premiums. Insurers often offer discounts to businesses that implement comprehensive fire safety measures, recognizing the reduced risk of fire-related claims.

Overall, the use of fire protection coatings in commercial and industrial settings provides peace of mind and financial benefits, making them a wise investment.

Residential Structures and Safety

In residential settings, fire protection coatings offer an added layer of safety for homeowners. These coatings can be applied to structural elements, such as wooden beams and steel supports, to enhance their fire resistance. By doing so, they help protect families and their homes from the devastating effects of fires.

Moreover, fire protection coatings can be used on interior surfaces, such as walls and ceilings, to further improve fire safety. This is particularly important in areas where fire hazards are present, such as kitchens and garages.

Homeowners can also benefit from the aesthetic versatility of fire protection coatings. Many of these coatings are available in a variety of finishes and colors, allowing them to blend seamlessly with the home’s decor.

By enhancing the fire resistance of their homes, homeowners can enjoy greater peace of mind and protection for their loved ones.

“Applying fire protection coatings in homes not only enhances safety but also preserves property value by preventing extensive fire damage.”

Historical and Heritage Sites

Historical and heritage sites require special consideration when it comes to fire protection. These sites often contain irreplaceable artifacts and structures that need to be preserved for future generations. Fire protection coatings offer a discreet and effective solution for safeguarding these valuable assets.

By using fire protection coatings, caretakers of historical sites can enhance the fire resistance of buildings without altering their appearance. This is crucial for maintaining the authenticity and aesthetic value of these sites.

Regulations and Standards in the UK

In the UK, fire protection coatings must comply with strict regulations and standards to ensure their effectiveness. These standards are designed to protect public safety and ensure that coatings perform as expected in the event of a fire.

Compliance with British Standards

British Standards (BS) outline the requirements for fire protection coatings, including their application, performance, and testing. Compliance with these standards is mandatory for manufacturers and installers, ensuring that coatings meet the necessary safety criteria.

By adhering to British Standards, property owners can have confidence in the performance of their fire protection coatings, knowing that they have been rigorously tested and approved for use.

Testing and Certification Requirements

Fire protection coatings must undergo extensive testing and certification to verify their effectiveness. This process involves simulating fire conditions and measuring the coating’s ability to protect materials from heat and flame.

Certification bodies, such as the British Board of Agrément (BBA), conduct these tests and issue certificates to products that meet the required standards. Property owners should look for coatings that have been certified by reputable organizations to ensure their reliability and performance. For more information on the significance of these coatings, explore the importance of protective coatings for industrial structures.

Industry Best Practices

Adhering to industry best practices is essential for ensuring the effectiveness of fire protection coatings. One of the most important practices is proper surface preparation. This step involves cleaning the surface thoroughly to remove dirt, grease, and other contaminants that could interfere with the adhesion of the coating. A well-prepared surface ensures that the coating bonds effectively, providing optimal fire protection.

Another key practice is applying the coating at the correct thickness. This is crucial because the thickness of the coating directly impacts its ability to protect against fire. Manufacturers typically provide guidelines on the appropriate thickness for different applications, and it’s important to follow these recommendations closely.

Regular inspections and maintenance are also vital. Over time, coatings can degrade due to environmental factors or wear and tear. Routine inspections help identify any areas that may need touch-ups or reapplication, ensuring that the fire protection remains effective.

Innovations and Future of Fire Protection Coatings

The field of fire protection coatings is continuously evolving, with new innovations and technologies emerging to enhance safety and performance. One of the most exciting developments is the use of advanced materials that offer improved fire resistance and durability. These materials are designed to withstand higher temperatures and provide longer-lasting protection, making them ideal for demanding applications. For more insights, explore the latest fire-resistant paints that are transforming the industry.

Another area of innovation is the development of coatings that are more environmentally friendly. As sustainability becomes a growing concern, manufacturers are focusing on creating products that have a lower environmental impact. This includes using non-toxic ingredients and reducing volatile organic compounds (VOCs) in the coatings.

New Materials and Technologies

Researchers are exploring a range of new materials and technologies to improve fire protection coatings. Nanotechnology, for instance, is being used to create coatings with enhanced fire resistance and thermal insulation properties. These coatings are designed to provide superior protection while being thinner and lighter than traditional options.

Additionally, smart coatings that can respond to environmental changes are being developed. These coatings have the ability to adjust their properties based on the surrounding conditions, offering adaptive protection against fire. This technology holds great promise for the future of fire safety, providing more efficient and effective solutions.

Environmental and Sustainability Considerations

As the demand for sustainable products grows, the fire protection industry is taking steps to address environmental concerns. Manufacturers are focusing on reducing the environmental impact of their coatings by using eco-friendly ingredients and minimizing waste during production.

Moreover, there is an emphasis on developing coatings that are recyclable or biodegradable, ensuring that they do not contribute to environmental pollution. These efforts are crucial for meeting the needs of environmentally conscious consumers and promoting sustainable practices within the industry.

Conclusion: Enhancing Property Safety with Fire Protection Coatings

Fire protection coatings are a vital component of any comprehensive fire safety strategy. By understanding the different types of coatings and their applications, property owners can make informed decisions to enhance the safety of their buildings. Whether for commercial, industrial, residential, or historical settings, these coatings provide essential protection against fire damage. Learn more about the importance of protective coatings for industrial structures.

By adhering to industry best practices and keeping abreast of the latest innovations, we can ensure that our fire protection measures remain effective and sustainable. Investing in high-quality fire protection coatings not only safeguards property but also saves lives, making it a worthwhile consideration for any building owner.

Frequently Asked Questions

What is the main purpose of fire protection coatings?

The main purpose of fire protection coatings is to enhance the fire resistance of materials and structures. These coatings help delay the spread of fire and prevent structural collapse, providing additional time for evacuation and emergency response. By doing so, they protect property and save lives.

How do intumescent coatings differ from other types?

Intumescent coatings differ from other types of fire protection coatings in that they expand significantly when exposed to heat. This expansion forms a protective char layer that insulates the underlying material from fire. Other coatings, such as cementitious fireproofing, provide fire resistance through different mechanisms, such as creating a physical barrier or reducing flammability.

Are there environmental concerns associated with fire protection coatings?

While some fire protection coatings contain chemicals that may have environmental impacts, the industry is moving towards more sustainable options. Manufacturers are developing eco-friendly coatings with reduced VOCs and non-toxic ingredients to minimize environmental harm. Additionally, efforts are being made to create recyclable or biodegradable coatings to further reduce their impact on the environment.