The Latest Innovations in UK Commercial Vehicle Body Shop Technology

Key Takeaways

- Advanced diagnostics tools in UK body shops have revolutionized vehicle repair, reducing repair times by up to 30%.

- Laser measuring systems ensure precision in repairs, minimizing errors and improving vehicle safety.

- Aluminum repair technology allows body shops to effectively handle the increasing number of aluminum-based vehicles.

- Smart welding machines enhance repair quality by providing consistent and reliable welds.

- Training and safety measures for electric vehicle repairs are crucial as EVs become more common.

Article-at-a-Glance

The UK commercial vehicle body shop industry is undergoing a technological transformation. With the integration of advanced diagnostics, laser measuring systems, and aluminum repair technology, body shops are more equipped than ever to handle modern vehicles. Additionally, the rise of electric vehicles (EVs) presents both challenges and opportunities for body shops, necessitating new training and safety protocols.

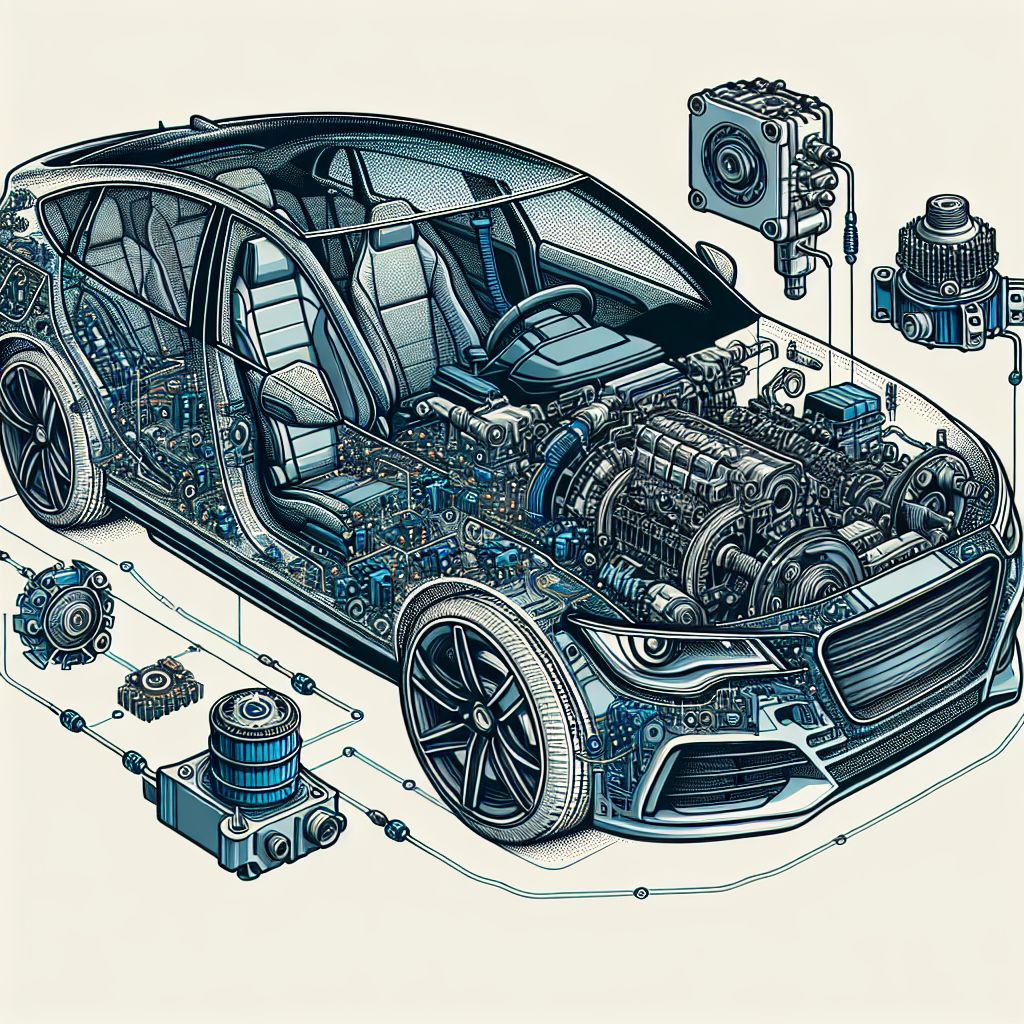

The Latest Innovations in UK Commercial Vehicle Body Shop Technology

In today’s rapidly evolving automotive industry, staying ahead of the curve is essential for any body shop. The UK is no exception, with commercial vehicle body shops embracing new technologies to improve efficiency and repair quality. Let’s dive into the world of cutting-edge vehicle repair and explore the latest innovations.

Introduction to Cutting-Edge Vehicle Repair

The landscape of vehicle repair has dramatically shifted over the past decade. Technological advancements have made it possible to perform repairs with unprecedented precision and speed. This evolution is not just about keeping up with trends; it’s about meeting the growing demands for efficiency and safety in vehicle repairs.

One of the most significant changes is the adoption of advanced diagnostics tools. These tools allow technicians to quickly and accurately identify issues, leading to faster repair times and improved customer satisfaction. As vehicles become more complex, the need for precise diagnostics has never been more critical. For those looking to ensure their vehicles are maintained efficiently, understanding what to look for in a reliable UK commercial vehicle body shop partner is essential.

Besides that, body shops are also investing in new equipment and technologies to handle the diverse range of vehicles on the road today. From traditional combustion engines to modern electric vehicles, each requires a unique approach to repair and maintenance.

Advanced Diagnostics Tools

Imagine being able to pinpoint a problem in a vehicle with laser-like accuracy. That’s the promise of advanced diagnostics tools. These devices use a combination of sensors and software to analyze a vehicle’s systems and identify issues that might not be visible to the naked eye.

For example, OBD-II scanners have become a staple in modern body shops. These devices connect to a vehicle’s onboard computer and retrieve diagnostic trouble codes (DTCs), providing technicians with valuable insights into the vehicle’s health.

“Advanced diagnostics tools have cut repair times by up to 30% in some cases, allowing body shops to serve more customers efficiently.”

But it’s not just about speed. Advanced diagnostics tools also improve accuracy, reducing the likelihood of misdiagnosis and ensuring that repairs are done right the first time. This not only saves time and money but also builds trust with customers, who can feel confident that their vehicle is in good hands.

Revolutionary Repair Techniques

With the foundation of diagnostics in place, the next step is implementing the actual repairs. This is where revolutionary repair techniques come into play. From laser measuring systems to aluminum repair technology, these innovations are reshaping the way body shops operate.

Laser Measuring Systems

Precision is key when it comes to vehicle repairs. Even the slightest misalignment can lead to significant issues down the road. Laser measuring systems address this challenge by providing highly accurate measurements of a vehicle’s frame and body components.

These systems use laser beams to scan the vehicle and create a detailed 3D model. Technicians can then compare this model to the manufacturer’s specifications, identifying any discrepancies and making the necessary adjustments.

“By ensuring precise alignment, laser measuring systems minimize errors and enhance vehicle safety, providing peace of mind for both technicians and vehicle owners.”

As vehicles become more advanced, the need for precise measurements will only grow. Laser measuring systems are a crucial tool in the body shop’s arsenal, enabling technicians to deliver repairs that meet the highest standards of quality and safety.

Handling High-Voltage Components Safely

As electric vehicles (EVs) become more prevalent on UK roads, body shops must adapt to the unique challenges they present. One of the most critical aspects of working with EVs is handling high-voltage components safely. These components can pose significant risks if not managed correctly, making safety a top priority for technicians.

High-voltage batteries and electrical systems require specialized knowledge and equipment to handle safely. Technicians must be trained to identify and isolate high-voltage areas before beginning any repair work. This involves using insulated tools and protective gear to prevent accidental shocks.

Training for Technicians on Electric Vehicle Repairs

To effectively service EVs, technicians need comprehensive training that covers the intricacies of electric drivetrains and high-voltage systems. This training ensures that technicians can safely diagnose and repair EVs without compromising safety.

Most importantly, training programs should focus on:

- Understanding EV architecture and components

- Safety protocols for handling high-voltage systems

- Diagnostic techniques specific to EVs

- Repair procedures for electric drivetrains and battery systems

By investing in training, body shops can equip their staff with the skills needed to handle the growing number of EVs on the road. This not only improves safety but also positions the shop as a leader in modern vehicle repair.

Integration of AI and Robotics

Artificial intelligence (AI) and robotics are revolutionizing many industries, and the automotive repair sector is no exception. These technologies offer exciting opportunities to enhance efficiency, accuracy, and productivity in body shops.

AI can be used to streamline various processes within a body shop. For instance, predictive analytics powered by AI can help forecast repair needs and optimize inventory management. This ensures that parts are available when needed, reducing downtime and improving customer satisfaction. For more on industry trends, check out the future of the UK car body repair market.

Automated Painting Systems

One of the most labor-intensive tasks in a body shop is painting. Automated painting systems, driven by robotics, are changing the game by offering consistent, high-quality finishes with minimal human intervention.

These systems use robotic arms equipped with spray guns to apply paint evenly across a vehicle’s surface. The benefits of automated painting systems include improved efficiency and precision, which are crucial as the UK car body repair market faces challenges in repair capacity.

- Reduced labor costs due to automation

- Consistent paint application, minimizing the risk of errors

- Faster turnaround times, allowing shops to handle more vehicles

By integrating automated painting systems, body shops can enhance their service offerings and provide superior results to their customers.

Robotic Assistants in Repair Processes

Beyond painting, robotics are also making their way into other repair processes. Robotic assistants can perform tasks such as welding, assembly, and even parts replacement with precision and speed. These robots work alongside human technicians, handling repetitive or dangerous tasks and allowing the human workforce to focus on more complex repairs.

This collaboration between humans and robots not only improves efficiency but also enhances safety by reducing the risk of injury during physically demanding tasks.

Sustainability in Body Shop Operations

With growing awareness of environmental issues, sustainability has become a key focus for many industries, including vehicle repair. Body shops are increasingly adopting eco-friendly practices to reduce their environmental impact and appeal to environmentally conscious customers.

| Sustainable Practice | Description | Environmental Benefits | Operational Advantages |

|---|---|---|---|

| Use of Water-Based Paints | Transitioning from solvent-based to water-based paints reduces VOC emissions. | Lowers air pollution and minimizes health risks for workers and customers. | Maintains high-quality finishes while meeting environmental regulations. |

| Energy-Efficient Equipment | Adopting tools like LED lighting and infrared curing lamps to reduce energy use. | Decreases carbon footprint through reduced energy consumption. | Reduces operating costs with faster drying times and longer-lasting equipment. |

| Recycling Programs | Recycling materials such as metal, plastic, and glass from repair processes. | Diverts waste from landfills and conserves natural resources. | Reduces disposal costs and enhances sustainability credentials. |

| Low-VOC Coatings | Using coatings with reduced volatile organic compounds. | Minimizes harmful chemical emissions and improves air quality. | Ensures compliance with environmental standards while maintaining durability. |

| Non-Toxic Adhesives | Replacing hazardous adhesives with non-toxic alternatives. | Protects workers and reduces chemical exposure in the environment. | Enhances workplace safety and aligns with eco-friendly goals. |

| Efficient Waste Management | Proper disposal of hazardous materials like paint thinners and solvents. | Prevents soil and water contamination from toxic substances. | Avoids penalties for improper waste disposal and supports regulatory compliance. |

| Employee Training | Educating staff on eco-friendly practices, such as reducing waste and energy use. | Promotes a culture of sustainability within the workplace. | Improves efficiency and reduces errors in sustainable operations. |

| Lifecycle Consideration | Evaluating the environmental impact of materials across their lifecycle. | Reduces overall resource usage by choosing sustainable materials upfront. | Lowers long-term costs by prioritizing durable, eco-friendly products. |

Environmentally Friendly Materials

One way body shops are becoming more sustainable is by using environmentally friendly materials. This includes low-VOC (volatile organic compounds) paints, which reduce harmful emissions, and recycled materials for repairs.

By choosing sustainable materials, body shops can minimize their ecological footprint and contribute to a cleaner, healthier environment.

Energy-Efficient Equipment Usage

Another aspect of sustainability is the efficient use of energy. Body shops can implement energy-saving measures such as LED lighting, energy-efficient HVAC systems, and solar panels to reduce their energy consumption. For more insights into the industry’s future, the UK body repair association has asked for reforms to secure the industry’s future.

These initiatives not only benefit the environment but also result in cost savings for the shop, making them a win-win solution.

Future Trends in Vehicle Body Repair

As technology continues to advance, the future of vehicle body repair looks promising. Emerging trends such as augmented reality (AR) and the Internet of Things (IoT) are poised to transform the industry further.

AR can be used to overlay digital information onto the physical world, providing technicians with step-by-step guidance for complex repairs. Meanwhile, IoT devices can monitor vehicle health in real-time, enabling predictive maintenance and reducing the likelihood of breakdowns.

By embracing these innovations, body shops can stay ahead of the curve and continue to deliver top-notch service to their customers.

Increased Use of Augmented Reality

Augmented Reality (AR) is set to become a game-changer in vehicle body repair. By overlaying digital information on the physical world, AR provides technicians with a new way to visualize and execute repairs. Imagine wearing AR glasses that guide you through the repair process, highlighting components that need attention and providing step-by-step instructions. This technology reduces errors and speeds up repairs, as technicians can see exactly what needs to be done without referring to manuals or guesswork.

Moreover, AR can be used for training purposes, allowing new technicians to gain hands-on experience in a controlled, virtual environment. This not only accelerates the learning process but also ensures that technicians are well-prepared before they work on actual vehicles. As AR technology becomes more affordable and accessible, its adoption in body shops is expected to grow significantly.

Predictive Maintenance through IoT

The Internet of Things (IoT) is revolutionizing how we approach vehicle maintenance. By equipping vehicles with IoT sensors, body shops can monitor the health of a vehicle in real-time, identifying potential issues before they become major problems. This proactive approach to maintenance can significantly reduce downtime and extend the lifespan of vehicles, supporting public transport efficiency.

For instance, IoT sensors can track engine performance, tire pressure, and brake wear, alerting technicians when maintenance is needed. This data-driven approach allows for timely interventions, reducing the likelihood of unexpected breakdowns and costly repairs. As more vehicles become connected, the role of IoT in vehicle maintenance will only continue to expand. Learn more about vehicle maintenance tips to ensure the longevity of your commercial fleet.

Conclusion: Embracing Innovation for a Competitive Edge

The future of UK commercial vehicle body shops is bright, thanks to the rapid adoption of innovative technologies. From advanced diagnostics and laser measuring systems to AR and IoT, these innovations are transforming the industry, making repairs more efficient, accurate, and sustainable. By embracing these technologies, body shops can not only improve their service offerings but also gain a competitive edge in an increasingly crowded market. For more insights, discover what to look for in a reliable UK commercial vehicle body shop partner.

As the automotive landscape continues to evolve, body shops must remain agile and open to new ideas. By staying ahead of the curve and continuously investing in the latest technologies, they can ensure long-term success and remain leaders in vehicle repair.

Frequently Asked Questions (FAQ)

What are the benefits of laser measuring systems?

Laser measuring systems provide highly accurate measurements of a vehicle’s frame and body components, ensuring precise alignment and minimizing errors. This enhances vehicle safety and improves repair quality, giving customers peace of mind.

By using laser measuring systems, body shops can deliver repairs that meet the highest standards, reducing the likelihood of future issues and building trust with their customers.

How do smart welding machines improve repair quality?

Smart welding machines offer consistent and reliable welds, improving the overall quality of repairs. These machines use advanced technology to adjust welding parameters automatically, ensuring optimal results every time.

With smart welding machines, technicians can achieve stronger, more durable welds, enhancing the safety and longevity of vehicle repairs. This technology also reduces the risk of human error, resulting in more efficient and effective repairs.

Why is training important for electric vehicle repairs?

Electric vehicles (EVs) have unique components and systems that require specialized knowledge and skills to repair safely. Training ensures that technicians understand EV architecture, safety protocols, and diagnostic techniques, allowing them to perform repairs confidently and competently.

What role does AI play in body shop technology?

AI streamlines various processes within a body shop, from predictive analytics for repair needs to optimizing inventory management. It enhances efficiency, accuracy, and productivity, allowing body shops to deliver top-notch service to their customers.

How can body shops become more sustainable?

Body shops can adopt eco-friendly practices such as using low-VOC paints, recycled materials, and energy-efficient equipment. These initiatives reduce the environmental impact of repairs and appeal to environmentally conscious customers.

Additionally, implementing energy-saving measures like LED lighting and solar panels can further reduce a shop’s ecological footprint and result in cost savings.